- Corporate

- Sustainability

Sustainability

As an internationally active company, Dillinger is part of global production chains. Only a common standard of ethical values and legal requirements within these supply chains enables us to design products sustainably and successfully. In our sustainability policy and cooperation with other stakeholders, we are guided equally by the fundamental freedoms of international conventions and the standards of the UN Global Compact.

Sustainable, responsible action is an elementary component of the Dillinger self-image. We have documented this attitude in the ethical guidelines of our group and in our vision. In this way, we actively assume responsibility for current and future generations of employees, for the environment, society and the region. The current sustainability report provides detailed information.

Within the diverse sustainability issues, climate change and the associated demand for massive and rapid CO2 reduction currently play a prominent role. We are convinced that in addition to environmentally friendly, i.e. CO2-reduced production, environmentally compatible products are also an important prerequisite for securing a long-term livelihood.

Steel and climate neutrality

Steel plays a big role in our daily lives: from cookware to bridges and from mobility to the power industry. Whether on water, on land or in the air, steel is one of modern industry's most important materials – and one of the most sustainable. With its 100% recyclability, steel is already the number one sustainable construction material.

Infinitely reusability of steel

At the end of their long service-lives, steel products become scrap – and thus an important feed material for the production of new steel. Application-orientated recycling assures infinite reuse. Just on half of Germany's annual steel output is produced from scrap. The recycling of around 20 million tonnes of steel scrap annually in Germany – equivalent to eight Eiffel Towers every day! – saves, for example, the mining of 1.5 tonnes of iron ore and 0.65 tonnes of coal, for instance, for every tonne of recycled scrap.

Steel as basis for regenerative energy

Renewable energy sources are our planet’s future. Ever scarcer fossil energy, and growing environmental awareness, are powering the expansion of the recovery of energy from regenerative sources. The high-performance material steel makes it possible and therefore is key to building a green economy. Steel is indispensable for constructing wind power installations as well as solar or pumped-storage power plants – and Dillinger, a market leader in the offshore wind industry, is globally recognized as a major partner for the power industry.

Dillinger for a green future

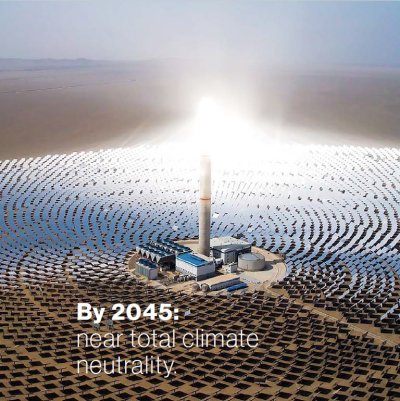

Steel will continue to play a major role in our daily lives. We at Dillinger will be part of a transformation process that changes the world – toward a greener and more sustainable way of life. With our products, we will be helping our customers reduce their own carbon footprints. The name Pure Steel+ stands for our path to green steel, for our CO2-reduced production route. The next big step towards a green future will take place in 2027, with the construction of the first electric arc furnace at the Dillingen site. This will also be accompanied by the start of production of carbon-reduced green heavy plate. Our goal by 2045: near total climate neutrality! For this innovation from the Saarland called Pure Steel+, we need support from the state, the federal government and the EU.

Certificates and memberships

Downloads

The video shows our path, subject to public subsidies, towards clean and climate-friendly steel production.

(Dauer: )

Quelle:

Innovative top-quality steel products, total orientation around our customers' needs and unceasing technological development in close cooperation with our partners form the basis of our success - as they have for more than 333 years.

© 2016 Dillinger All rights reserved.

Contact

AG der Dillinger Hüttenwerke

Werkstraße 1

66763 Dillingen/Saar

Tel.: +49 6831 47 0

Fax: +49 6831 47 2212

E-Mail: info@dillinger.biz

Imprint

| Data privacy statement

| T&C