- News & Information

- Press Releases

Seminar on thermomechanically rolled steel revealing cost benefits in steel construction

21. November 2017

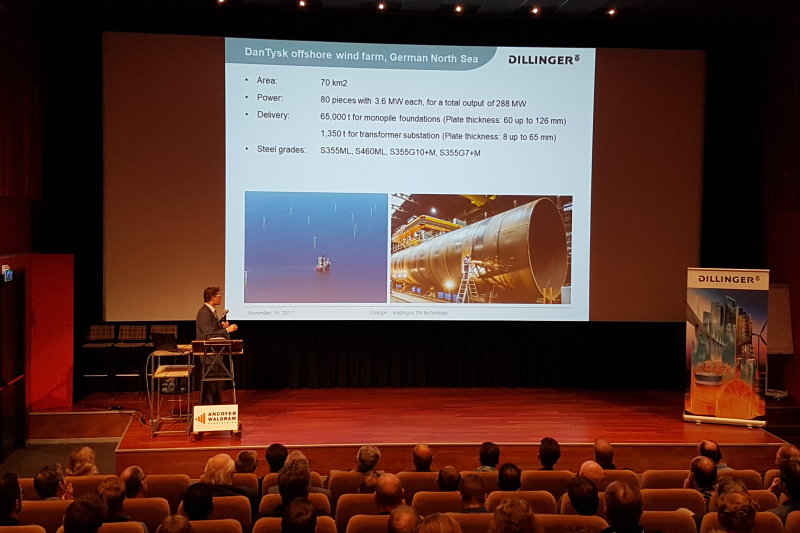

AncoferWaldram Steelplates and Dillinger organized a seminar about thermomechanically rolled (TM) steel in The Netherlands, on 15th November, 2017.

Among the 90 participants were welding engineers, consultants, QA engineers, procurement officers, as well as government officials etc. In short, everyone that is involved in the processes of material selection, design and quality assurance.

The seminar provided an excellent platform to exchange knowledge and experience around the applications and cost saving benefits of TM material in production processes. Dillinger explained its leading production process of TM steels resulting in a constant and beneficial quality. New investments in continuous casting and rolling technology today allow for new super-heavy world record TM plates. External experts gave an overview on the application of TM steel in daily practice and the benefits during the welding process as well as safety margins in qualification procedures.

We look back on a successful afternoon with informative presentations and enthusiastic discussions where it became clear that the use of TM steel in fabrication processes is a key for reliable and cost efficient steel structures.

Please find here a summary of the Dillinger presentations

-

Leading in TM steel technology

Wolfram Hölbling, 2017, Size: 1234 KBytes -

Cost efficient and reliable fabrication with TM steel

Tobias Lehnert, 2017, Size: 1272 KBytes

Further information:

Innovative top-quality steel products, total orientation around our customers' needs and unceasing technological development in close cooperation with our partners form the basis of our success - as they have for more than 333 years.

© 2016 Dillinger All rights reserved.

Contact

AG der Dillinger Hüttenwerke

Werkstraße 1

66763 Dillingen/Saar

Tel.: +49 6831 47 0

Fax: +49 6831 47 2212

E-Mail: info@dillinger.biz

Imprint

| Data privacy statement

| T&C