- E-Service

- Useful tools

- Hollomon parameter calculation

- Hollomon examples

Examples for Hollomon Calculation

Examples for using the "Hollomon-Parameter"

- Calculation of the HPtotal of a complex heat treatment procedure

- Calculation of the holding time for given HP and holding temperature

- Calculation of the holding temperature for given HP and holding time

1. Calculation of the HP total of a complex heat treatment procedure

Objective:

You may need to calculate the total HP-value of the following heat treatment cycle:

- Plate thickness 37 mm

- Tempering condition: 710 °C/30'

- PWHT1condition: 680 °C/300' with a heating- resp. cooling rate of 70 °C/h

- PWHT2 condition: 680 °C/400' with a heating rate of 30 °C/h and a cooling rate of 60 °C

Solution:

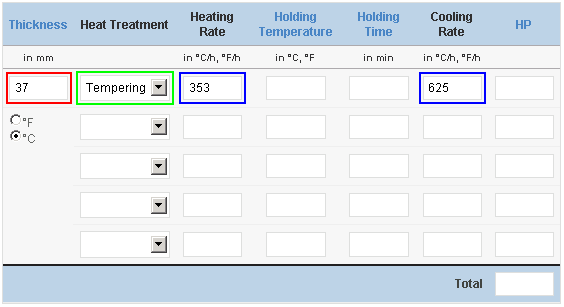

1. Start the program "Calculation of the Hollomon-Parameter" and enter the plate thickness

Start the program "Calculation of the Hollomon parameter" and enter the plate thickness: Select the heat treatment "Tempering". In this mode the program automatically calculates the heating- and cooling rate for a given thickness.

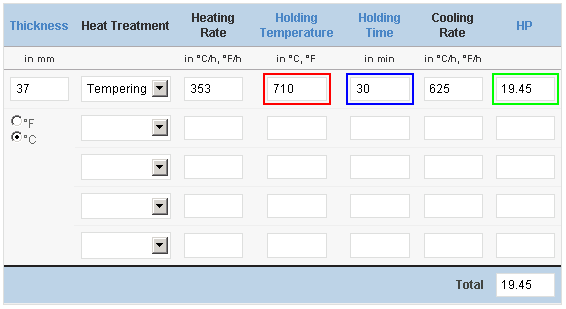

2. Enter the tempering condition as mentionned above:

Enter the "Tempering condition" 710°C/30' by entering the holding temperature and the holding time. The resulting Hollomon parameter HP of this single heat treatment "Tempering" is shown in the same line after a <CLICK> in the green marked area.

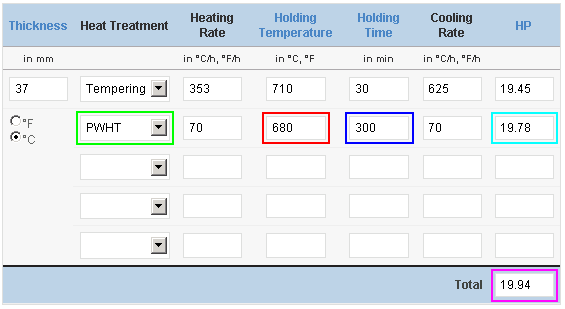

3. Enter the PWHT1 condition as mentionned above:

Enter the "PWHT1" 680 °C/300' in the second line. Select the heat treatment mode "PWHT" with a default heating/cooling rate of 50 °C/h; this can be changed as in our expamle to 70 °C/h. After this you may enter the holding temperature and the holding time of the PWHT1 condition as already described for "Tempering" in the second step. As indicated before the calculated HP-value of the PWHT1 heat treatment is given in the same line after a <CLICK> in the marked area. The total Hollomon Parameter of the combined heat treatment meaning "Tempering" + "PWHT1" is indicated as HPtotal.

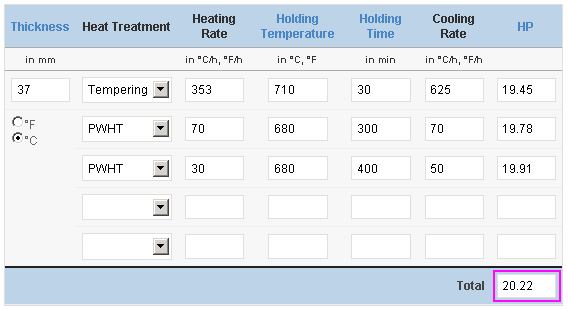

4. Enter the PWHT2 condition as mentionned above

Enter the "PWHT2" condition exactly as described in the third step. The resulting picture is then the following. The calculated Hollomon parameter of the complete heat treatment cycle "T + PWHT1 + PWHT2" is given here as HPtotal.

2. Calculation of the holding time for given HP and holding temperature

Objective:

You want to know the holding time which you have to choose for a tempering heat treatment with the following parameters:

- The plate thickness is 55 mm.

- requested HP=20.1

- tempering temperature 700 °C.

Solution:

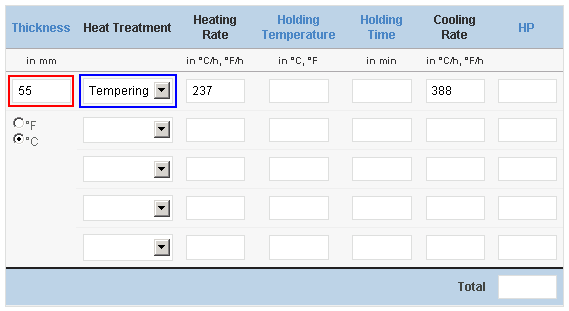

1. Start the program and enter the plate thickness.

Start the program and enter the plate thickness; choose the heat treatment mode "Tempering". As described in example 1, the heating- and cooling rates are calculated automatically when the plate thickness is entered.

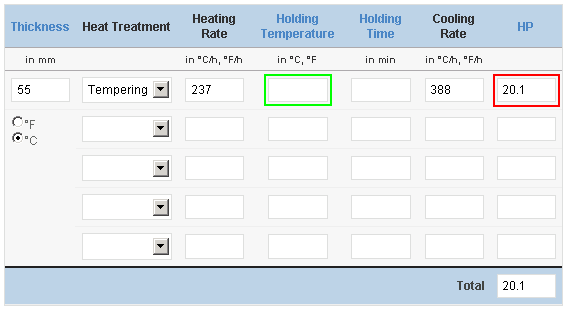

2. Enter the Hollomon parameter

Insert the Hollomon parameter 20.1 into the foreseen field, move the mouse to the green marked area and perform a <CLICK>

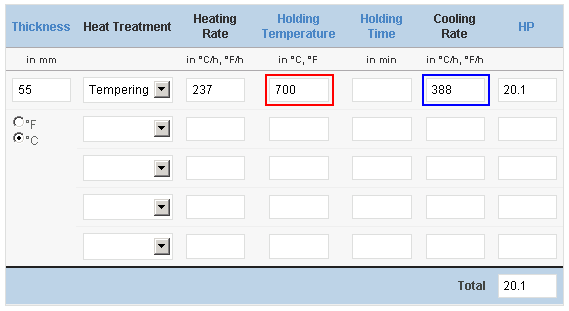

3. Enter the holding temperature.

Insert the holding temperature 700°C.

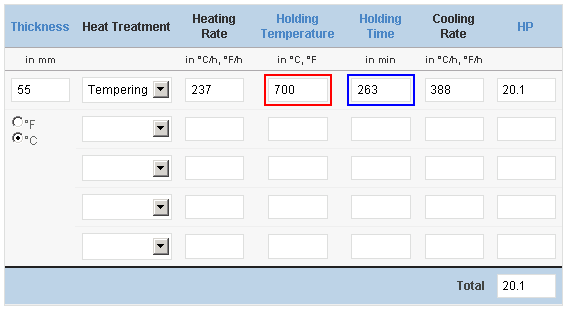

4. Calculation of the holding time

After a <CLICK> in the blue marked area the program calculates the corresponding "holding time".

3. Calculation of the holding temperature for given HP and holding time

Problem:

You want to know which holding temperature you have to choose for a tempering heat treatment with the following assumptions:

- The plate thickness is 100 mm.

- requested HP=19.7

- tempering temperature of 90 minutes.

Solution:

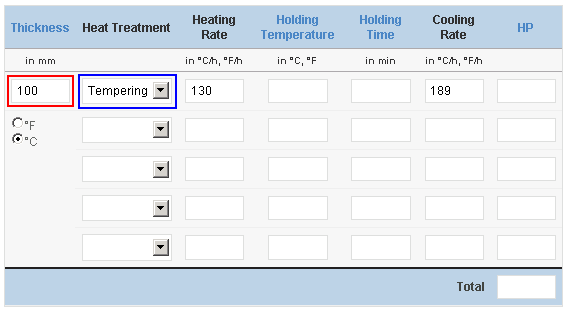

1. Start the program and enter the plate thickness.

Start the program and enter the plate thickness. Choose the heat treatment mode "Tempering". The heating- and cooling rates are calculated automatically as described in example 1.

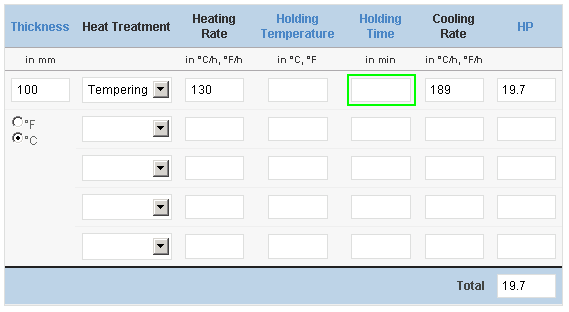

2. Enter the Hollomon parameter

Enter the requested Hollomon Parameter 19.7 which should be achieved with the tempering into the foreseen field, move the mouse into the green marked area and perform a <CLICK>

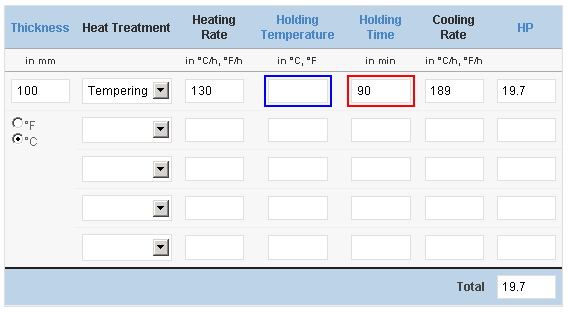

3. Enter the holding time.

Insert the time of 90 minutes.

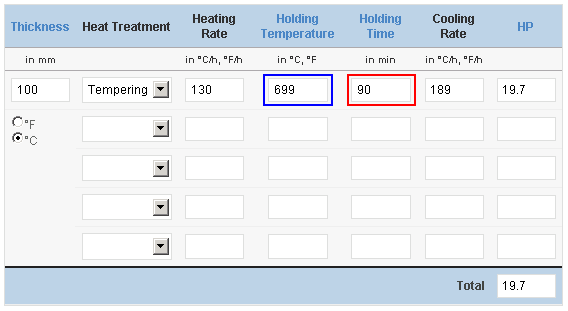

4. Calculation of the holding temperature

After a <CLICK> within the blue marked field, the program calculates the corresponding holding temperature.

Innovative top-quality steel products, total orientation around our customers' needs and unceasing technological development in close cooperation with our partners form the basis of our success - as they have for more than 333 years.

© 2016 Dillinger All rights reserved.

Contact

AG der Dillinger Hüttenwerke

Werkstraße 1

66763 Dillingen/Saar

Tel.: +49 6831 47 0

Fax: +49 6831 47 2212

E-Mail: info@dillinger.biz

Imprint

| Data privacy statement

| T&C